Embedded Software Development for Hearing Diagnostics Device

Networking connections introduced Hearing Diagnostics to i4PD whilst on a quest to improve hearing testing at a community level. After establishing that Hearing Diagnostic’s project and i4 Electronics’ embedded software development capabilities were aligned, we were chosen as the design partners for their ‘lead generating’ diagnostic hearing test device.

We were responsible for the mechanics, industrial design, electronics, and software development for the Hearing Diagnostics device.

Client

Hearing Diagnostics

Work category

Services

Prototyping & Testing

Electronic Engineering

Software Development

Mechanical Engineering

Industrial Design

Manufacturing Support

Project Management

Precision ensured through advanced IMU and embedded software development engineering.

Product Overview

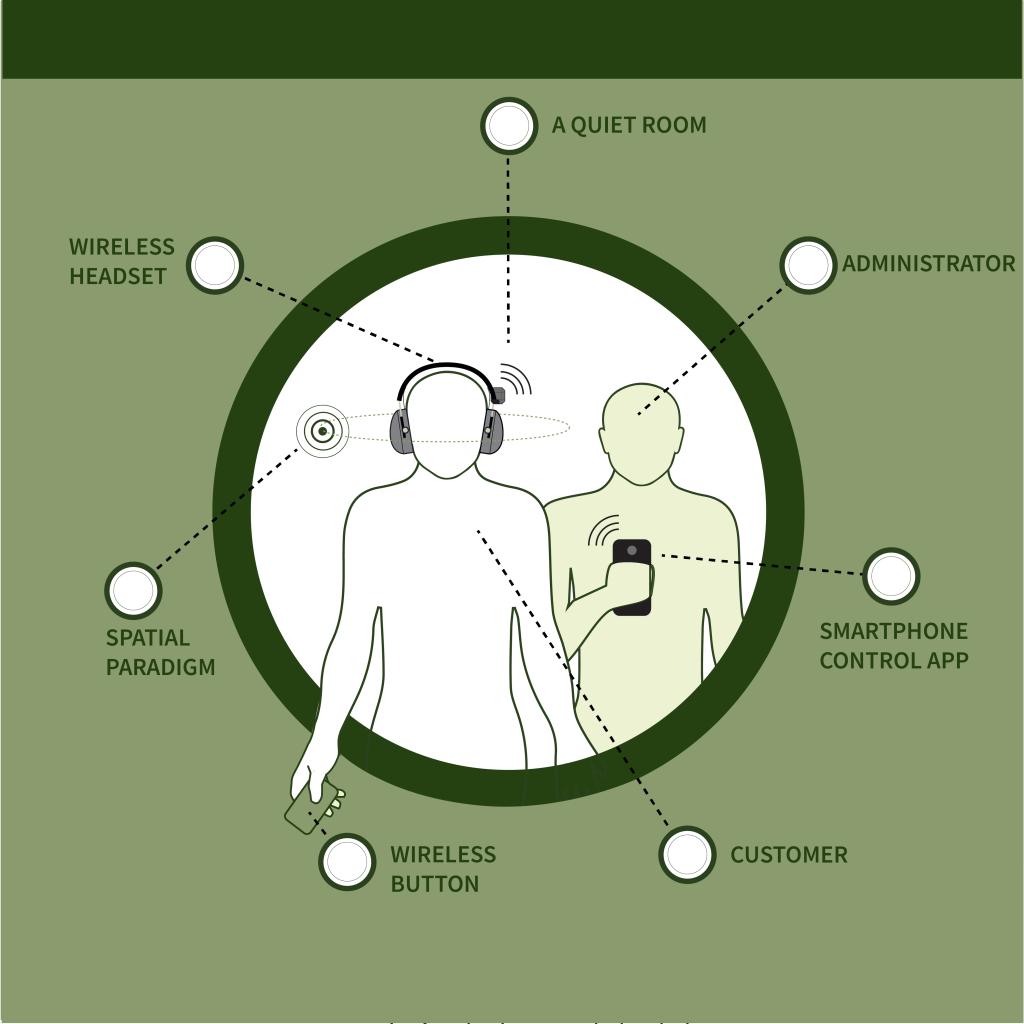

Traditional hearing tests typically require a qualified professional to undertake the test and then translate the data. The Hearing Diagnostics product offers a user-friendly alternative that can be used in pharmacies, high street drug stores and other informal environments for quick and accessible hearing assessments.

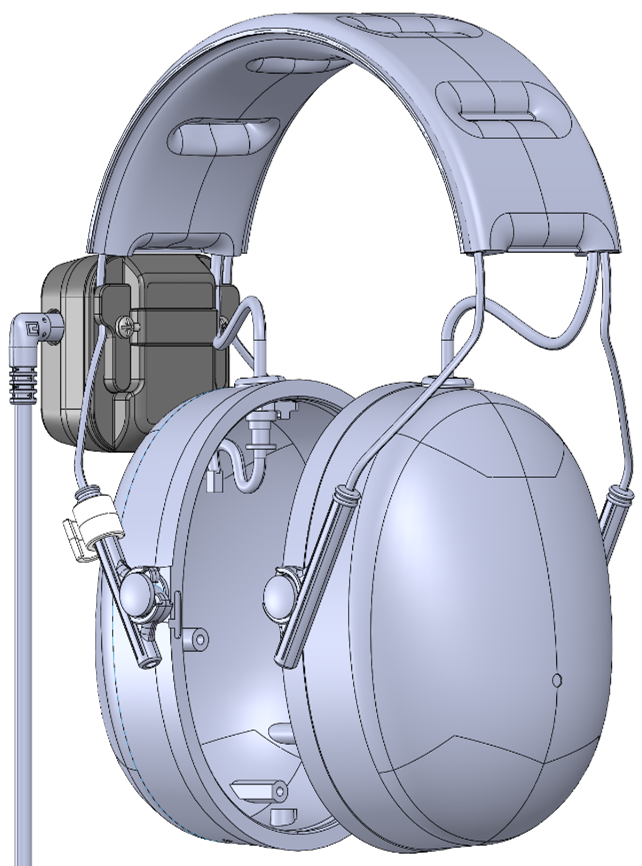

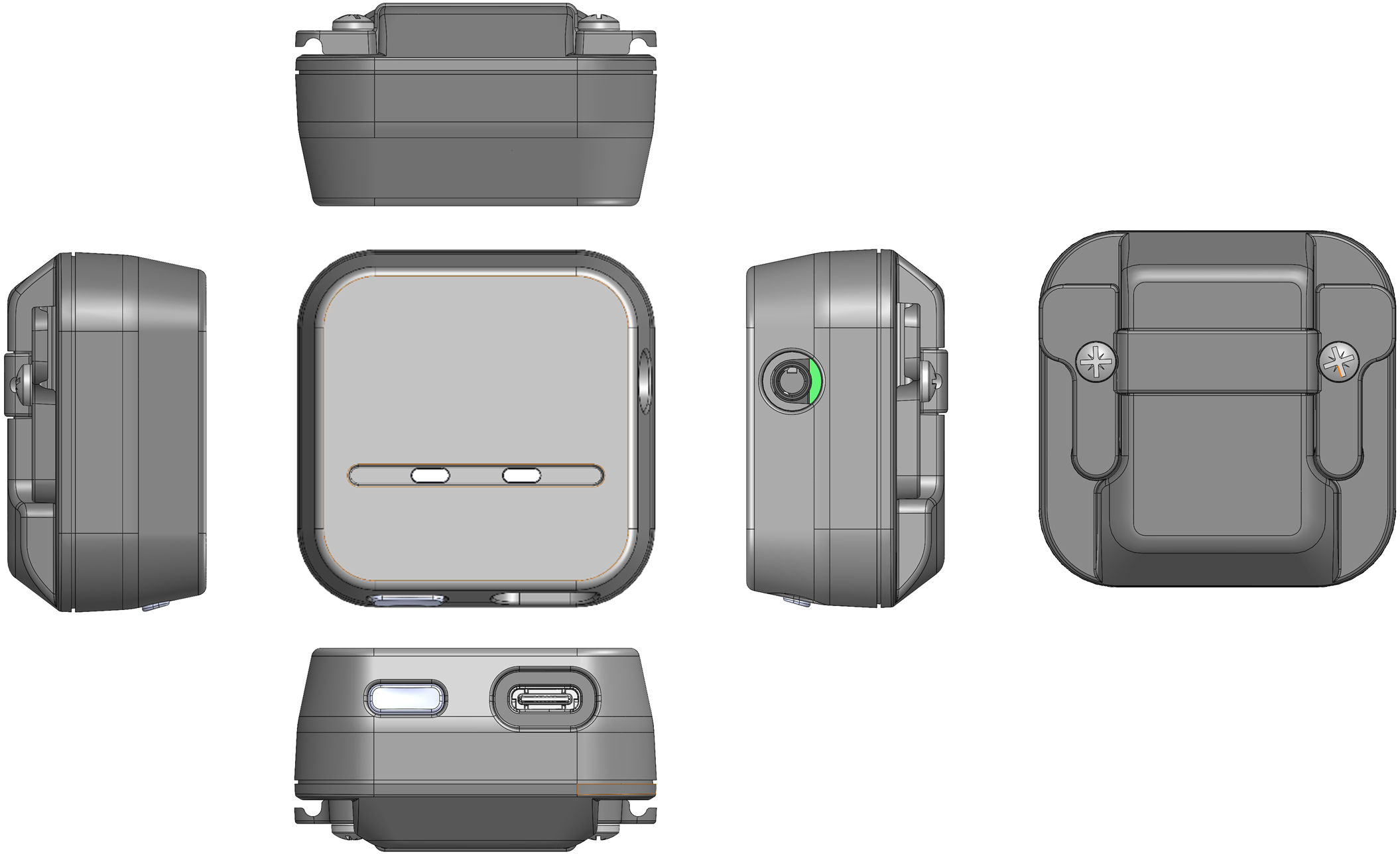

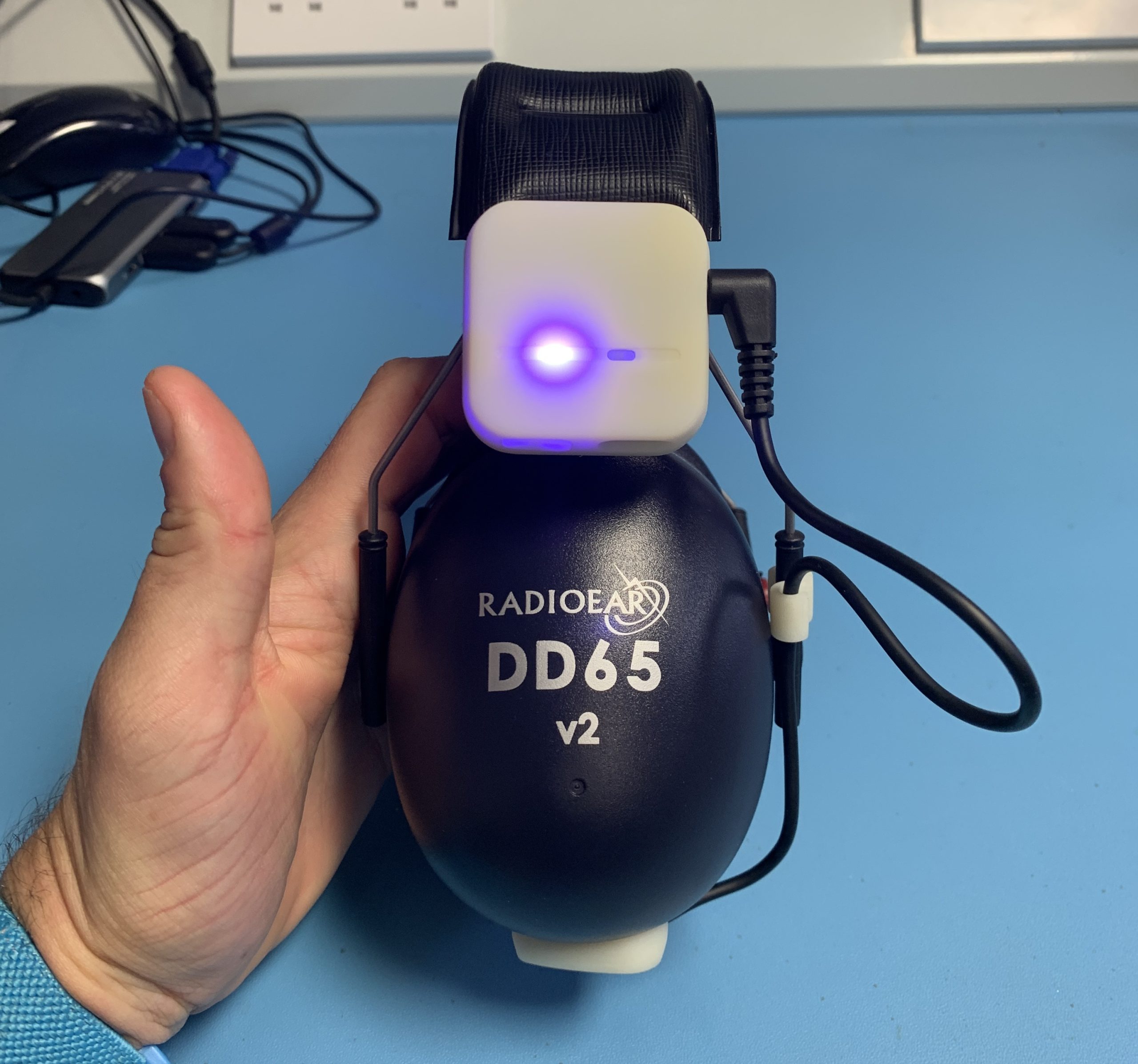

The product was created by attaching an intelligent ‘diagnostic’ unit to a pair of headphones. The headphones play sounds at different frequencies and volumes, and users turn their heads to locate the sounds. The device gathers data from these movements and translates it into metrics on hearing ability. The unit conducts the test and gathers the data, sending the required frequencies and signals to the earcups of the headphones.

Key Elements

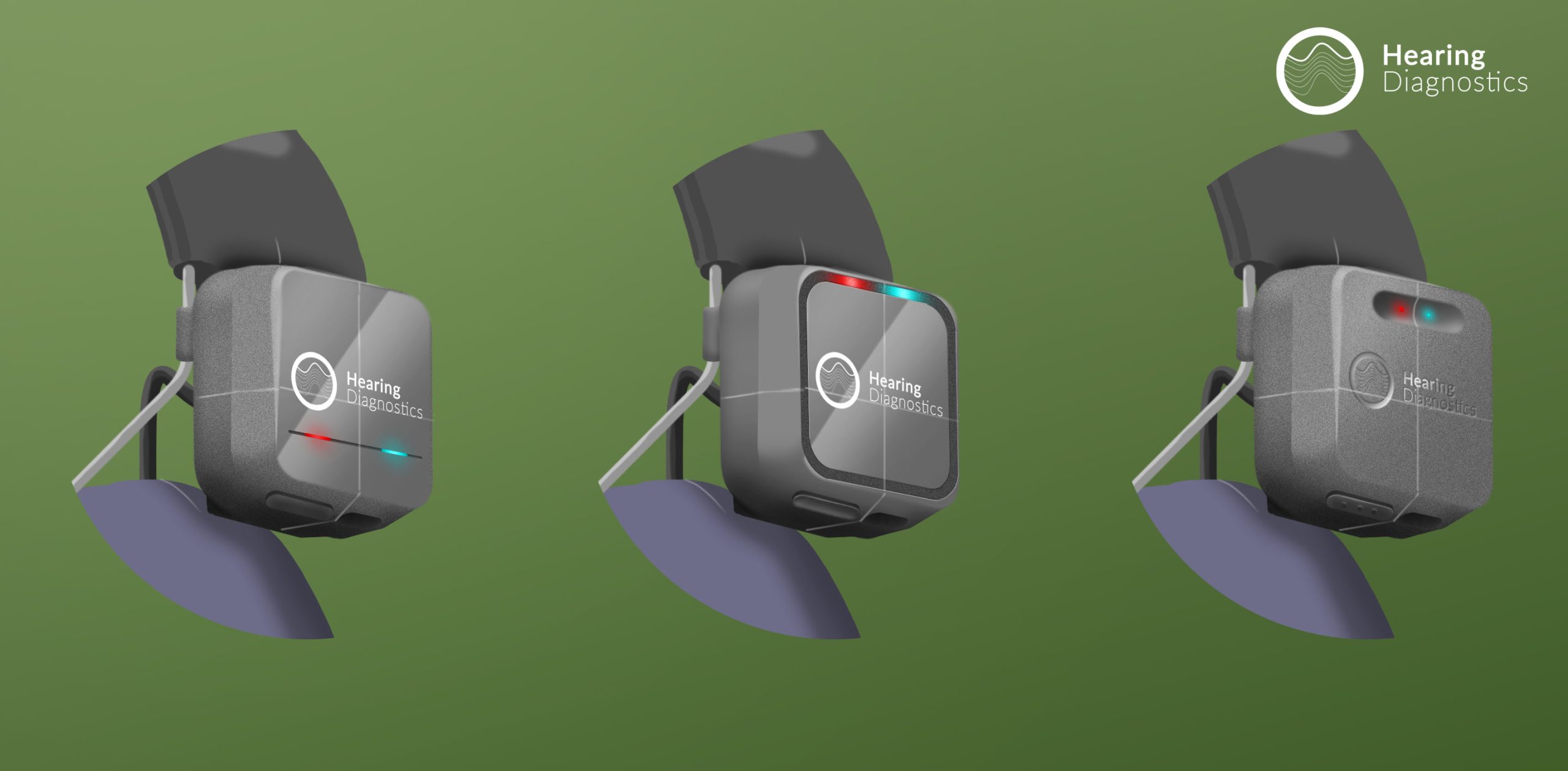

Industrial Design and Integration with Headphones

The Hearing Diagnostics unit needed to be compatible with certified audiology headphones. After exploring various options, it was agreed that placing the unit above the ear cup was the most effective design choice. Despite making the headphones asymmetrical, the device is so light (around 50 grams), that balance and comfort is not disrupted. The final design is an efficient integration and reduces unnecessarily long lengths of wire due to its proximity to the earcup.

The industrial design team designed a strong clamp system for attaching the device to the headband of the headphones. The design had to withstand the natural flexes and stretches of headphone use.

Having both the electronics and industrial design teams work together in our studio facilitated a very smooth integration process. This internal collaboration allowed us to speed up the process and meet the requirements effectively.

Electronics and Embedded Software Development

Our team developed the platform and low-level software, including the OS (operating system). We ensured the device’s software communicated effectively with the other electronics in the product and provided test code to speed up the development process.

The device features a high-end Nordic nRF5340 microcontroller, running Zephyr OS. Additionally, it includes a GreenPAK programmable logic circuit for tasks like button press detection, device reset, and battery charging indicators.

We conducted thorough testing on the devices electronics components to ensure their long-term reliability. Our engineers spent time testing and tuning the stereo D/A converter to ensure it could drive the headphones across a very wide dynamic range, essential for the requirements of the hearing test. The circuit was modified to prevent the device from producing dangerously loud sounds, even at full volume.

IMU and Development Kits

During this project we had to navigate a volatile components market (Covid-19 shortages) which made finding a suitable inertial measurement unit (IMU) very challenging. Our good supplier relationships and reliable components library was massively helpful for damage limitation during this time and helped keep things on track. Unfortunately, we also experienced issues with faulty development kits during this project. Our in-house electronics lab allowed our engineers to quickly remedy the issues, re-soldering and modifying the kits to keep the project moving, this was especially important due to the slow components market.

Testing and CE Marking

Extensive data logging was required to ensure the device’s accuracy. It needed to be proven that the device’s spatial awareness was faultless. The device has to accurately know where it’s positioned so that the diagnostics are accurate.

To complete the project, we delivered clear build instructions and block diagrams for Hearing Diagnostics to use when assembling their units. The device achieved CE certification, proving it to be a market ready product.

We like to find new, better and efficient ways of doing things. Contact us to discover how i4 Product Design can solve your current design challenge and take your product to the next level.

Schedule a call today

"i4 Electronics understood our requirements well and were collaborative throughout"