Embedded firmware development consultancy for real time fluid rheology

Stream Sensing specialise in industry leading fluid analysis systems. We were approached as an embedded firmware development consultancy to help with updating the software elements of their industrial fluid rheology measurement product. The system will be used by global FMCG production plants to monitor the properties of fluids such as shampoo or ketchup, ensuring that they have the right consistency during their production.

Client

Stream Sensing

Work category

Services

Embedded Software

Systems integration

Prototype and Test

Background

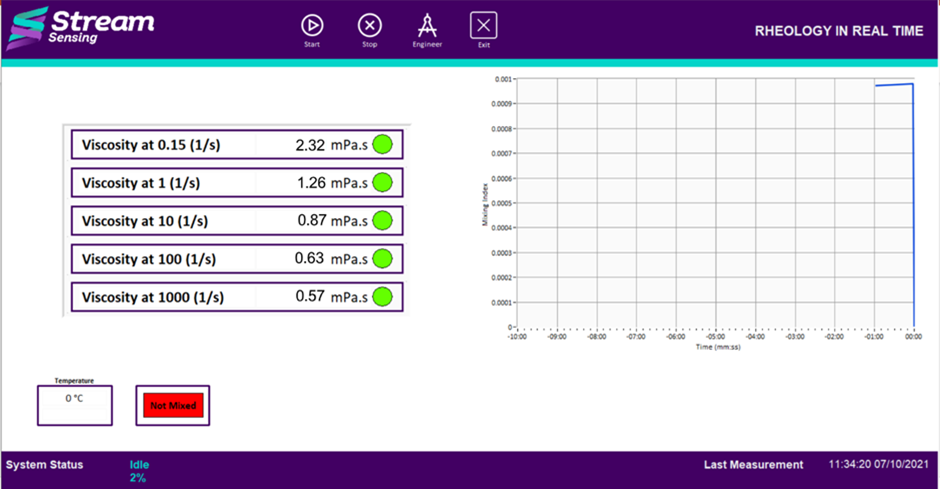

Stream Sensing were looking to update the current version of their product, which was built in LabVIEW and supported by tools written in MATLAB. The Stream Sensing team desired a software and UI update to increase the capability and user-friendliness of their existing system. Stream Sensing remained focussed on the theory and science behind the fluid analysis process, so they decided to outsource the technical software elements of the project to i4PD.

The initial project work spanned roughly seven months, with some additional finalisation work extending slightly longer.

Project Brief

Stream Sensing had several key objectives:

- Port the legacy code from LabVIEW and MATLAB to a C/C++ based architecture.

- Design a system capable of processing and analysing fluid data faster than the previous model, improving overall performance.

- Create a new more flexible data format for recording results.

- Develop a modular system capable of handling multiple data streams and producing results more efficiently.

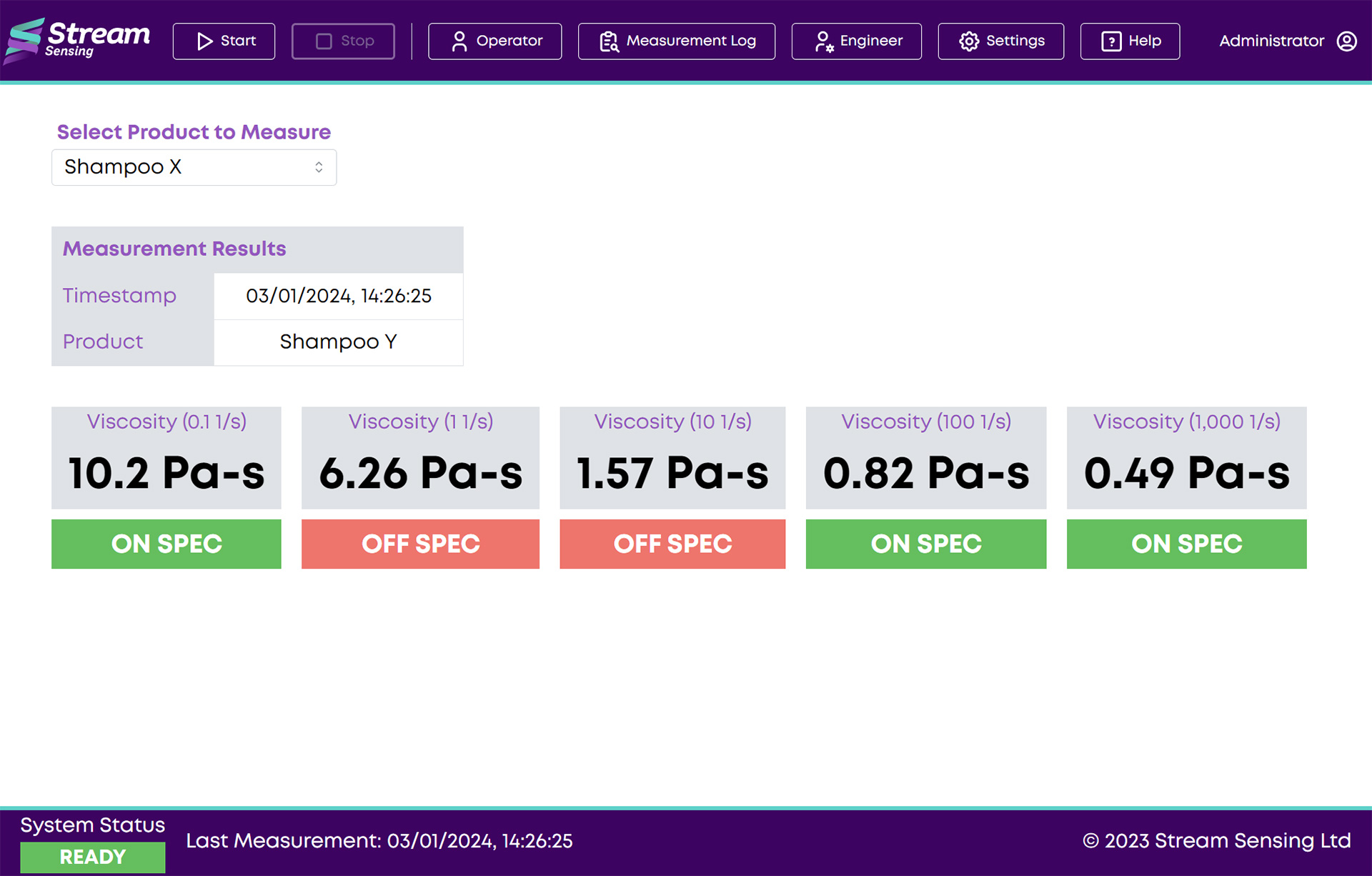

- Implement a web-based user interface in collaboration with Firefinch software.

“Working with i4PD was a great experience throughout the software development process. From the outset, i4 electronics understood our requirements well and were professional and collaborative throughout. We are very happy with the outcome: high-quality software which not only meets our requirements now but is also easily extendable to add future features.”

Jack Andrews, Stream Sensing

The Stream Sensing System

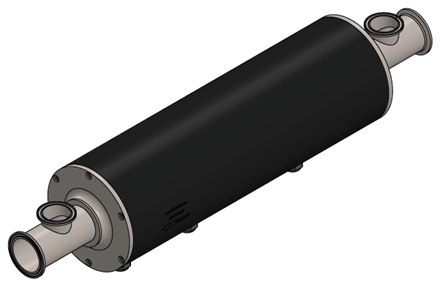

The system measures the rheology of fluids by analysing flow at measured points in the pipe. An example would be its use in FMCG production plants where products like shampoo need to be monitored to ensure they are neither too thick nor too thin. The system employs Electrical Resistance Tomography (ERT), using a ring of electrodes around the pipe to measure electrical currents at measured interval points. The data generated creates a detailed map of the fluid’s behaviour, which is then used to calculate flow speed and rheology.

Approach

i4 focussed on several technical areas:

Porting Code:

We were provided with initial hardware and legacy code in LabVIEW and MATLAB from the previous version of the product. Our software team ported this into a C/C++ codebase. Simpler modules and common code were written in C, with C++ reserved for the more complex tasks like tomography and the analysis of neural network results.

Neural Network Implementation:

Stream Sensing have successfully trained a neural network model to process the tomography results data. We integrated their model with our newly developed system, feeding it the data and ensuring the correct rheology data output.

Web UI Integration:

We collaborated with our partners at Firefinch software to design a user-friendly web interface. Our team determined what data the system needed to feed to the UI and ensured that there was smooth communication between both the backend and frontend of the product.

Remote Debugging & PLC Interface:

One significant technical challenge we overcame was debugging the system remotely. The system is designed to interface with PLCs (Programmable Logic Controllers) for use in FMCG factories. We collaborated with Stream Sensing via VPN, linking our software to their hardware in Manchester without needing to be physically on-site.

Matrix Maths Optimisation:

The tomography and neural network processing involve intensive matrix maths operations. We successfully integrated a third-party matrix library (saving time and expenses), which was a crucial component in handling the vast amounts of data being processed at fast speeds.

Communication Between Modules:

We designed and implemented an architecture based on MQTT (Message Queuing Telemetry Transport), which allowed the different system modules to communicate seamlessly. This method enabled loose coupling between components, resulting in a more maintainable and modular system.

Output

The updated Stream Sensing software is a faster, more modular, and user-friendly solution, ready for use in global FMCG plants. By porting code to a C/C++ architecture, integrating a neural network for real-time analysis, and helping to enhance the UI, we significantly improved performance. The result is a future-proof Stream Sensing system that ensures precise fluid rheology monitoring at an industrial scale.

We like to find new, better and efficient ways of doing things. Contact us to discover how i4 Product Design can solve your current design challenge and take your product to the next level.

Schedule a call today

“i4 is an exceptional electronics design partner whose innovative solutions consistently exceed our expectations”